OrganIC

fertIlIzER

technologIes

OrganIC

fertIlIzER

technologIes

We infused our expertise in Biohumus Organic Fertilizer manufacturing with the essence of the COMPOSTER label.

We create transformative organic fertilizer factory projects that facilitate the composting of all organic waste, manufacture, and set up the machinery.

Utilizable Resources: Farm animal resources, slaughterhouse resources, food processing facility resources, vegetable and fruit resources, park garden pruning resources, etc.

About Us

Biohumus Teknoloji

Anonim Sirketi

Biohumus Teknoloji

Anonim Sirketi

BIOHUMUS TEKNOLOJI A.S. has embarked on a journey of significant investments to cultivate its unique technological production system for the creation of organic fertilizers. Leveraging its expertise and insights acquired in organic fertilizer production, the company also innovates machinery.

Under the COMPOSTER brand, zero waste recycling is achieved by transforming organic waste like animals, plants, food, and slaughterhouses into high-value organic fertilizers. All machines and equipment utilized in the production systems are manufactured, assembled, and installed by our company.

Our skilled and dedicated team conducts all research and development for our machines and equipment, which are 100% locally made. The facilities we establish have the potential to attain international organic certification for the organic fertilizer they generate, based on the properties of the raw materials utilized.

We share our expertise and experience in setting up organic fertilizer factories that handle farm and biogas plant wastes on a large scale. Our focus is on providing small-scale machines for sustainable waste management to schools, hospitals, restaurants, hotels, shopping malls, public institutions, and organizations. We tailor solutions and projects to each institution's waste management needs. Our aim is to promote a more efficient, sustainable, and resource-conscious zero-waste system.

We are thrilled to announce that our organic fertilizer production system is highly sought after both locally and globally. BIOHUMUS TEKNOLOJI A.S. will persist as a trailblazer in technology and innovation within organic fertilizer production.

What is Composting?

Compost is an organic fertilizer derived through a proprietary closed process, where plant and/or animal organic waste is mineralized by microorganisms. It is utilized in bioreactors manufactured under the Composter brand by Biohumus Technology, an eco-friendly conditioning technology.

This fertilizer is free from any chemical additives or treatments.

Compost generated in enclosed bioreactors exhibits content levels 20 times greater than compost created through heap blending. In heap-mixed compost production, the humic fulvic acid content typically ranges from 5-10%, whereas composts produced in enclosed bioreactors may contain 35-40% humic fulvic acid.

Automated regulation of all compost production parameters minimizes odors released into the environment and enhances compost quality. Furthermore, this approach shields the compost from external influences. Particularly in open-air compost production, there is a risk of harmful flies and insects nesting during storage. This could result in heightened pest presence in the environment, necessitating increased pesticide usage.

Closed bioreactors enable high-quality and standardized production while minimizing energy expenses. This technology promotes sustainable agriculture and environmental protection through the efficient utilization of organic waste.

Closed bioreactors enable high-quality and standardized production while minimizing energy expenses. This technology promotes sustainable agriculture and environmental protection through the efficient utilization of organic waste.

Compost enhances soil fertility, nourishes plants, and sustains natural cycles. Consequently, compost generated in enclosed bioreactors plays a significant role as an eco-friendly fertilization method.

Producing Compost with a Bioreactor

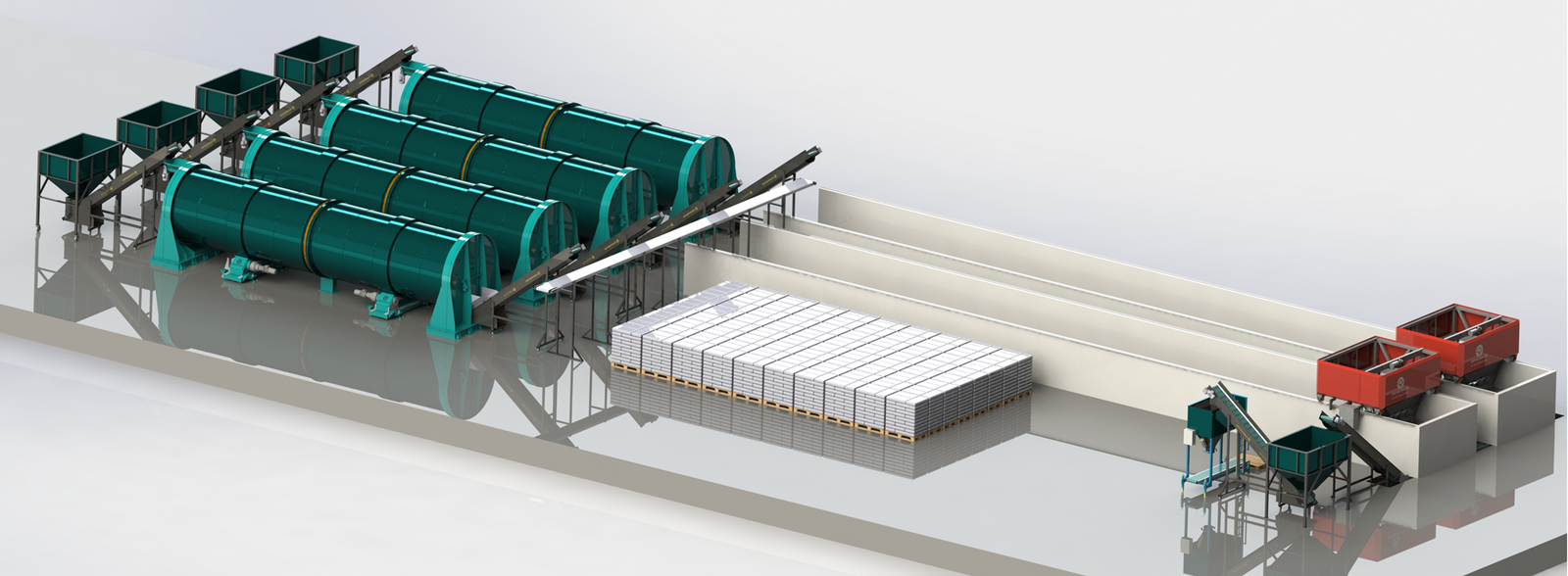

Biohumus Organic Fertilizer is generated through the processing and aerobic fermentation of animal or vegetal wastes in a closed-system bioreactor or closed-system bulk bed pulverizer unit.

The system is fully automated and can be optionally operated with artificial intelligence support based on the recipe.

Personnel and energy expenses are minimal. Animal waste can serve as a standalone raw material; Cattle, sheep, goat, and camel waste can be directly utilized. To aerobically ferment plant waste, animal waste, or organic live activator is necessary.

Our expert technical teams and academic experts support projects to compost waste effectively using appropriate technology.

In the end, there is only one habitable world for all of us.

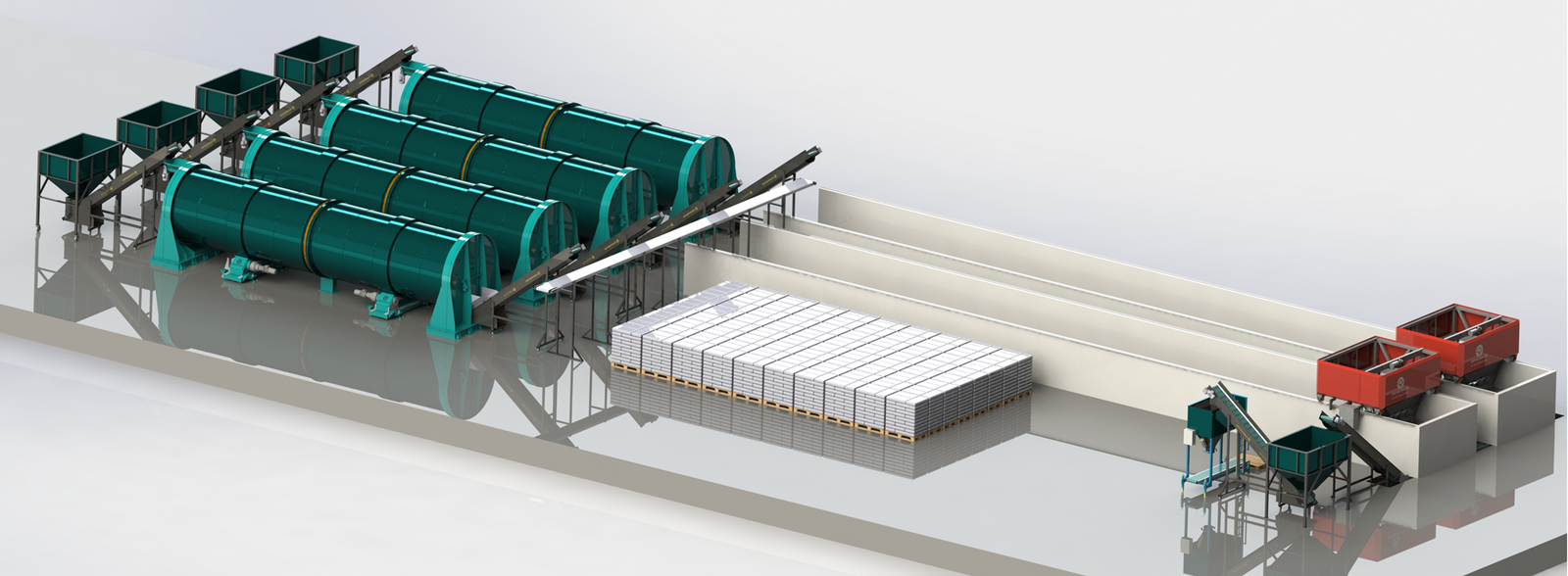

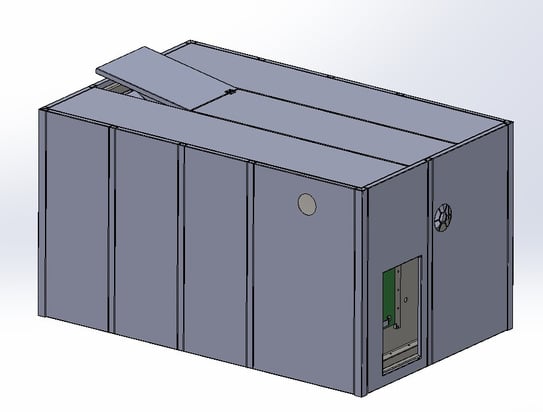

Bioreactor Modeling

CMP 54 SP Models

CMP 54 SP Models

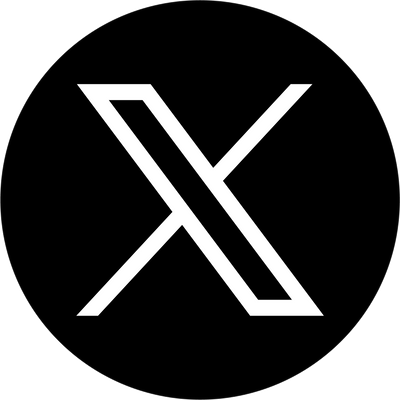

It is a controlled mechanization system that incorporates Ecological Conditioning Technology to facilitate the organic fertilizer formation process. This system guarantees the swift, secure, and controlled development of organic fertilizer by maintaining a consistent aerobic environment.

The CMP 54 series Bioreactor enables the production of organic fertilizer at global standards without the need for catalysts or chemical inputs.

Cattle farm waste and source-separated organic waste can be utilized as raw materials for the system.

The system is designed for continuous operation 24/7.

Composted materIal 54 specIfIcatIon

It possesses a volumetrIc capacIty of 54 cubIc meters.

CMP 54 SP facilitates the effortless installation of high-capacity organic fertilizer systems due to its modular design, enabling seamless capacity expansion.

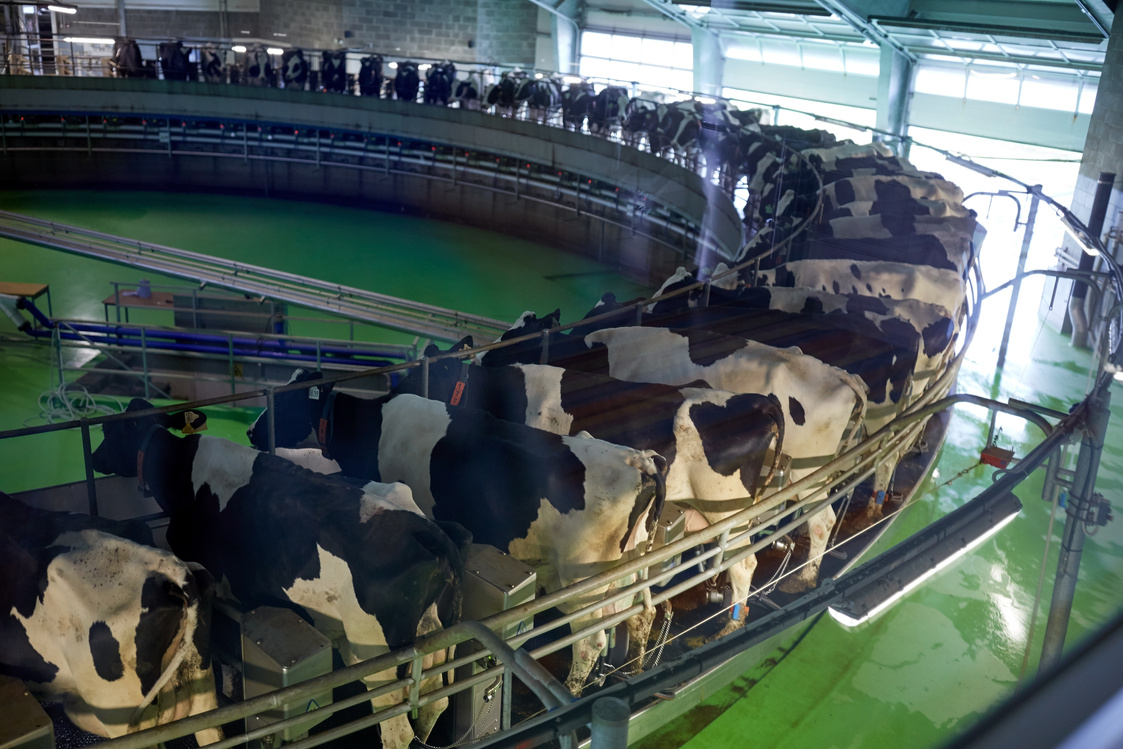

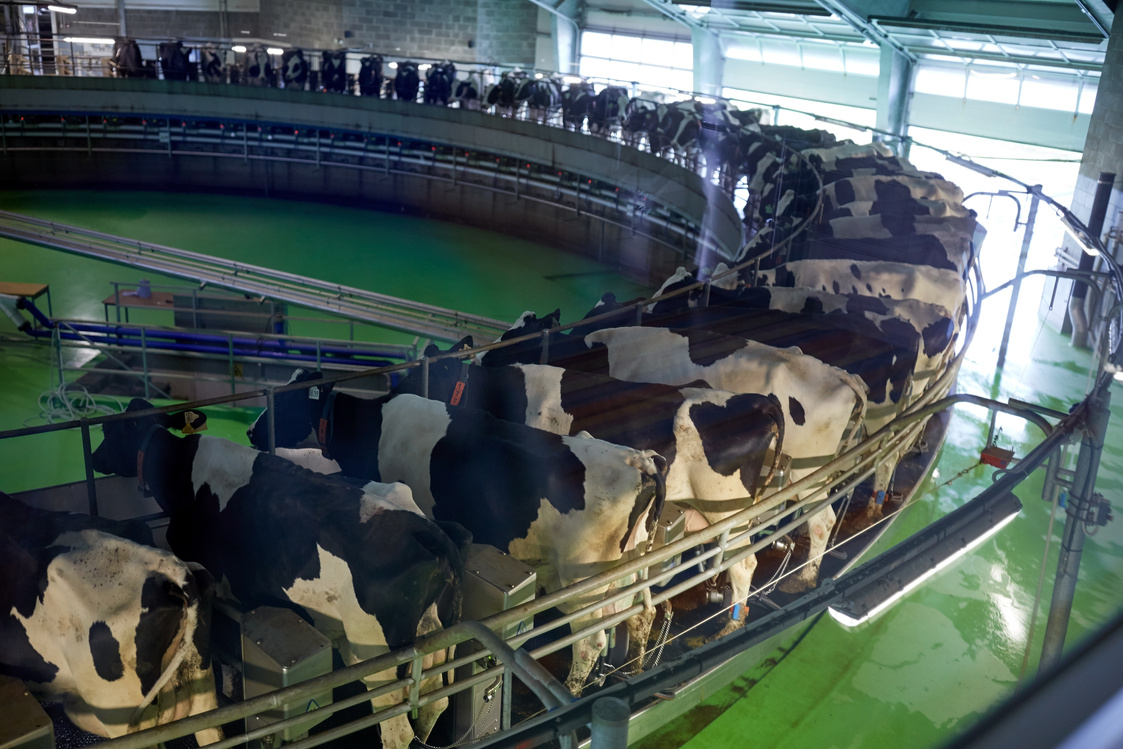

Animal waste can serve as a standalone raw material. Horse, cow, sheep, goat, and camel waste can be directly utilized. These wastes are commonly employed in cattle fattening farms, dairy farms, sheep fattening farms, goat fattening farms, camel fattening farms, and egg chicken farms.

For the aerobic fermentation of plant waste, animal waste, or organic live activator is necessary.

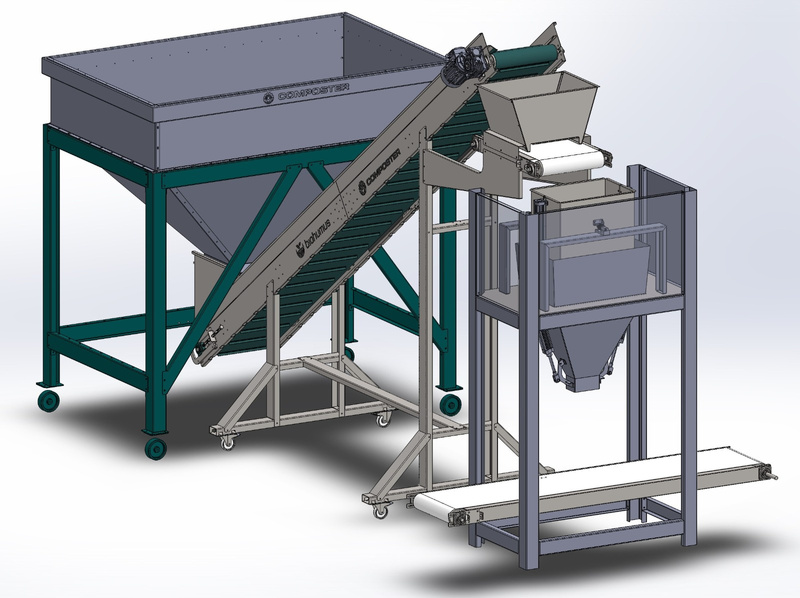

Pulverizer PLV 4000 SP

Pulverizer PLV 4000 SP

Pulverizer PLV 4000 SP

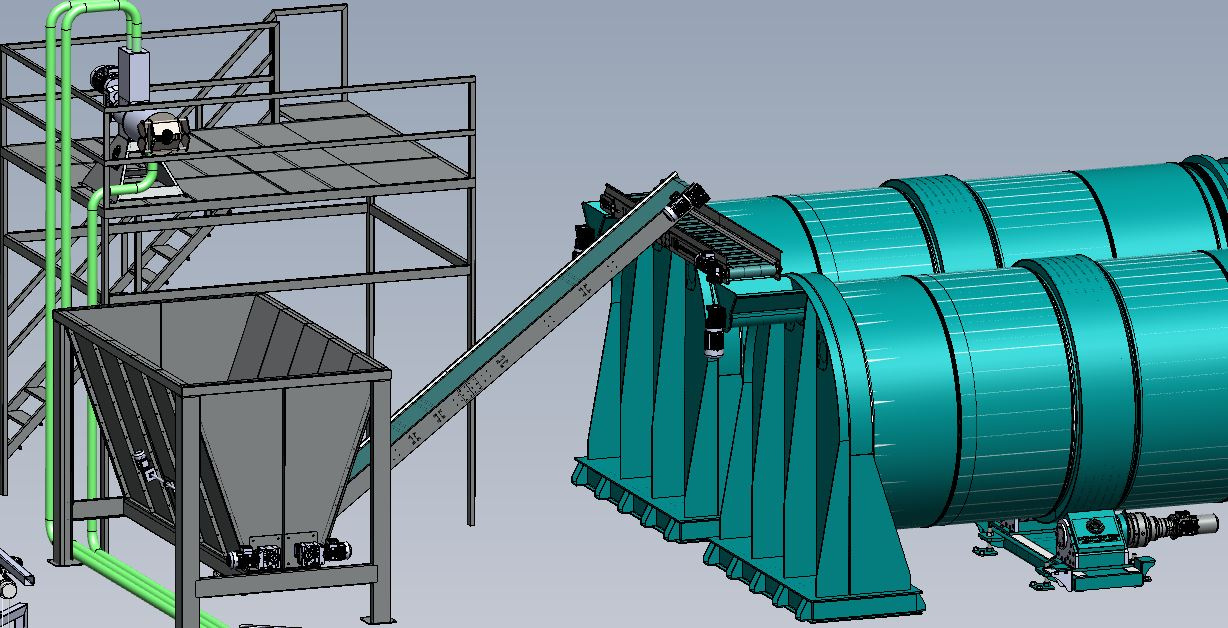

The Pulverizer PLV 4000 SP comes in two variants.

- It facilitates moisture removal from the fertilizer obtained post-bioreactor, automates inventory management, and ensures product stability prior to packaging.

- It is utilized for automated controlled compost production in a direct heap bed, serving as an optimal and cost-effective system for the controlled compost cycle of high capacity and mixed raw materials.

PLV 4000 SP The hall has a capacIty of 600 cubIc meters

wIthIn Its 100-meter expanse.

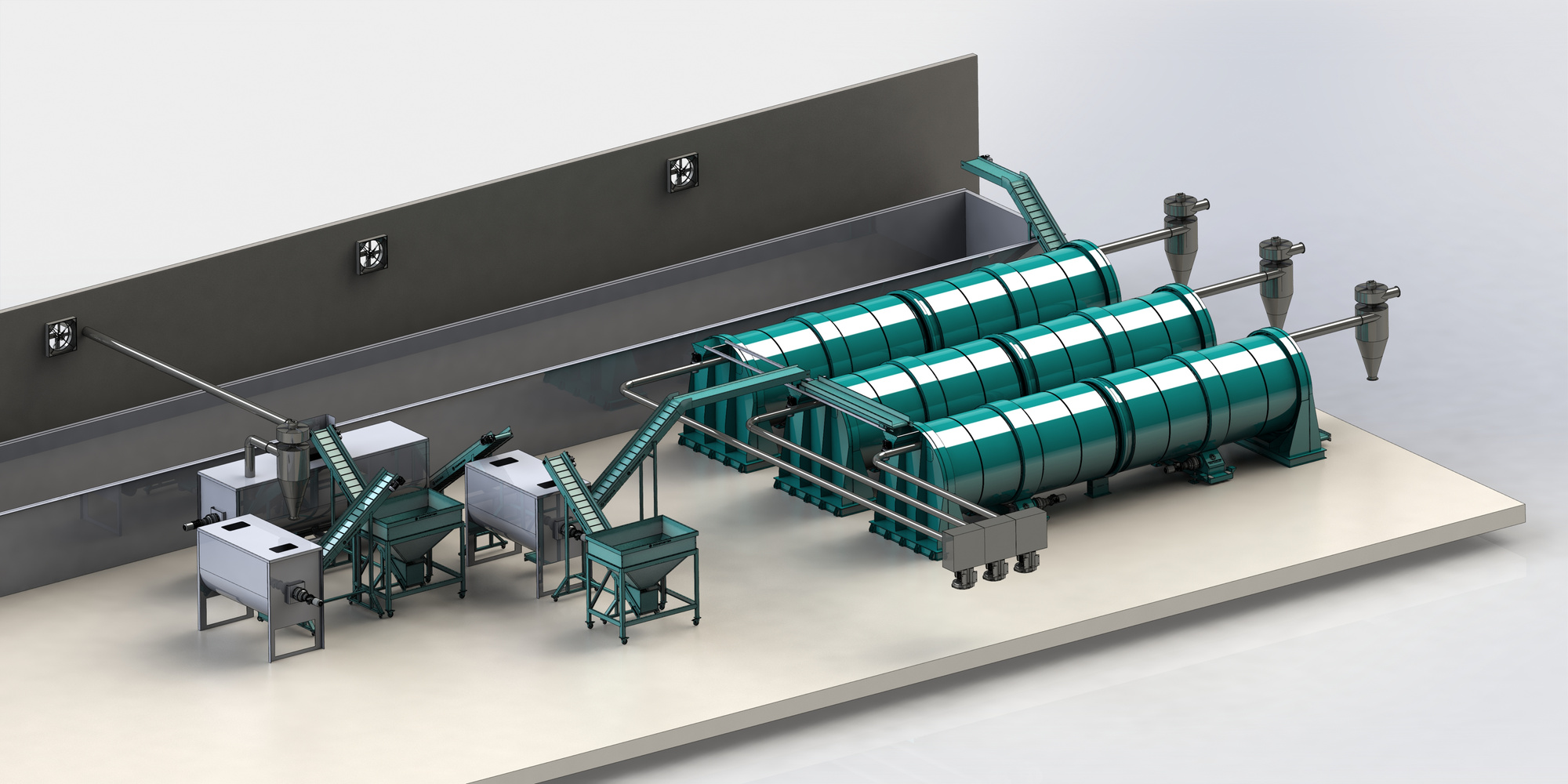

Bioreactor Modeling

CMP 500 SP Models

CMP 500 SP Models

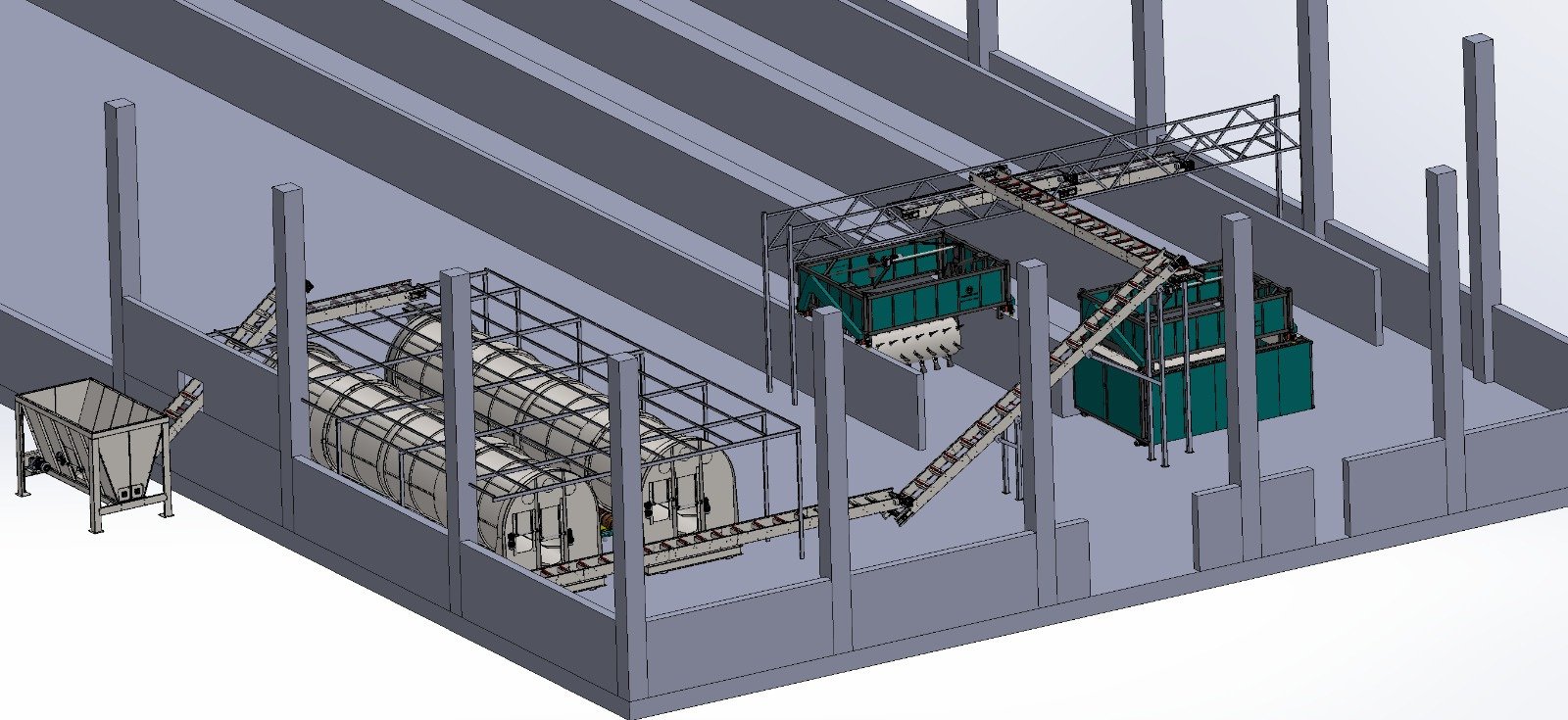

It is a controlled mechanization system that facilitates the organic fertilizer formation process with Ecological Conditioning Technology, ensuring rapid, safe, and controlled formation of organic fertilizer by maintaining the aerobic environment's continuity.

The CMP 500 SP series Bioreactor enables the production of organic fertilizer at global standards, particularly utilizing farm animal waste, without the need for catalysts or chemical inputs.

Cattle farm waste and source-separated organic waste can be utilized as raw materials for the system.

The system is designed for continuous operation 24/7.

The CMP500 sp has a volumetric capacity of 600 liters.

CMP 500 SP specializes in recycling organic waste, particularly in the context of Zero waste. It has a loading capacity of 200-400 liters, varying based on the type of waste and mass balance density.

Animal waste can serve as a standalone raw material. Horse, cow, sheep, goat, and camel waste can be directly utilized. These waste products are particularly prevalent in cattle fattening farms, dairy farms, sheep fattening farms, goat fattening farms, camel fattening farms, and egg chicken farms.

To facilitate the aerobic fermentation of plant waste, animal waste, or organic matter, an activator enzyme is required. This enzyme is customarily formulated and provided by our company, tailored to the specific type of waste being processed.

Packaging of Organic Fertilizer

PCK 5100 SP Models

PCK 5100 SP Models

The organic fertilizer packaging unit was designed considering the moist and bond-holding nature of organic fertilizer, unlike other packaging machines.

Between 150 and 200 packages can be produced per hour.

The weighing unit operates by conducting accurate weighings within the 1-50 kg range.

With the optional automatic sewing machine, the capacity increases by 30%.

The system operates in conjunction with the feeding bunker and feeding conveyor. A mixing screw feeding bunker may also be utilized based on customer requirements.

All system equipment is modular and can be mobilized with bolted fasteners.

PCK 5100 specIfIcatIon

CapacIty: 150-200 pIeces per 25 kg

Utilizing Compost Fertilizer Effectively

Utilization in Vegetable Cultivation

You can cultivate your vegetables in any desired environment using compost organic fertilizer. Biohumus organic fertilizer products are adequate for nourishing your plants. For vegetable seedlings, 100-150 grams per seedling will suffice. On average, 50-100 grams per seed will be enough for seed planting.

Utilization on Fruit Trees

Biohumus Organic Fertilizer is suitable for all fruit trees, whether in closed or open root sapling plantings. For new plantings and young fruit trees, 1-2 kg is recommended, while 3-4 kg is suitable for adult trees.

Utilization in Gardening and Landscaping

Compost organic fertilizer can be safely applied to all outdoor and indoor plants, including grass and lawn areas. It fulfills the nutritional requirements of plants in landscape settings and promotes sustainable water usage due to its 300% water retention capacity.

Advantages of Compost Fertilizer

PhysIcal Advantages

BIologIcal Advantages

It inhibits plant stress. |

It inhibits the accumulation of harmful chemicals in the soil, aiding in soil renewal. |

It enhances plant immune system. |

It enhances the soil's biological vitality. |

It enhances beneficial soil organisms like worms, actinomycetes, mycorrhiza, and supports other microbial fertilizers. |

Increased plant productivity correlates with higher biological activity in the soil, which is sustained by biohumus. |

It supplies advantageous aerobic bacteria for plants and soil. |

It enhances the soil's absorption of nutrients by plants. |

It nourishes beneficial soil-dwelling organisms. |

It enhances plants' resistance to pests and diseases. |

SoIl benefIts

It controls soil acidity levels. |

It inhibits the accumulation of harmful chemicals in the soil, aiding in soil renewal. |

It possesses a high rate of Humic Fulvic Acid. |

It inhibits soil salinization. |

Soils deficient in organic matter hinder nutrient absorption by plants, leading to nutrient leaching. Organic matter addresses this issue by enhancing cation exchange capacity. |

It supplies plant nutrients like nitrogen, phosphorus, and potassium, functioning as a slow-release fertilizer. |

It facilitates the absorption of essential nutrients by the plant that are unavailable in the soil. |

It enhances saline and infertile soils using chemical fertilizers. |

It decreases the quantity of chemical fertilizer required for soil application. |

It facilitates the swift breakdown of pesticides in the soil, diminishing the likelihood of phytotoxicity. |

Contact

+90 258 266 13 12

info@biohumus.com.tr

( Factory) Yumrutas Mahallesi / 3 sokak No:2 Acipayam - Denizli - Türkiye

( Office Center ) Zeytinkoy Mah. 5071 Sokak No:1 20160 Pamukkale - Denizli - Türkiye

Biohumus organic fertilizer social media profiles